Siempelkamp Particle Board Line to produce 500 cu m per day of 4ft wide boards SOLD

General InformationGeneral Information

FOR GENERAL INFORMATION WE HAVE TO INFORM YOU OF THE FOLLOWING:

This schedule has been prepared solely for the guidance of prospective purchasers and in no way constitutes, and at no time will it be deemed to constitute, an offer or contract or any part of an offer or contract. Additionally, no warranty is given to the accuracy of any measurement, specification or other details whatsoever given within this document.

Whilst every reasonable effort has been made to verify any statement, description or comment made within the document, for avoidance of doubt it is emphasised that the purchaser must make their own enquiries and satisfy themselves.

Please note that all offers are made as lying and subject to contract.

Further technical details, photographs and videos may be available on request.

If you have any specific requirements for wood panel or paper making machinery or wish to sell your spare or redundant machinery then please contact us on john@linnmachinery.com

For more information contact john@linnmachinery.com.

X

- Screw feeder from chip pile.

- Belt conveyors.

- Metal detector.

- Belt magnet.

- PALLMAN PZKR 14/450 ring flaker with spare ring.

- Knife grinder.

- Chain conveyor with extraction fan and cyclone.

- Belt conveyors to feed flake pile.

- New in 1996.

- Wood flakes feed (New in 1996).

- Screw feeder from flake pile.

- Belt conveyors feeding to dosing bin.

- Dosing bin with bottom feed screw.

- Sawdust feed (New in 1996).

- Walking floor and screw feeder.

- Vibrating screen.

- Belt magnet.

- Belt conveyors feeding to dosing bin.

- Dosing bin with bottom feed screw.

- RECALOR combustion chamber with LBE 12MW dual fuel burner.

- Dust silo and feed system.

- Oil tanks and feed system.

- New in 1996.

- Wood separation using main cyclone

- 3 dust extraction lines with

- 3 Fans

- 3 banks of cyclones

- Firefly system

- PAL designed and supplied system.

- New in 1996.

- 2 PAL screens.

- 1TEXPAN screen.

- PAL wind sifter system.

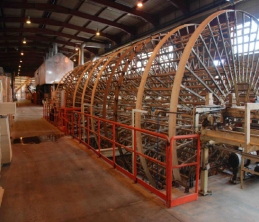

- Line relocated to site in 1996 by Siempelkamp, originally supplied 1988.

- Mat reject system new in 2000.

- 8 day light press

- Master board

- Finished size 1220 mm x 7320 mm.

- Thickness 8 mm to 30 mm.

- Density 600 to 750 Kg/m3/.

- Siempelkamp 8 day light particleboard press relocated to site in 1996 by Siempelkamp engineers, with

- New wood preparation equipment in 1996.

- New RECALOR combustion chamber, dryer and dust extraction equipment in 1996.

- New PAL screening equipment in 1996.

- IMAL blending equipment.

- TEXPAN forming stations.

- New Siempelkamp pre press equipment in 1996.

- New mat reject equipment installed in 2000.

- Newly added parts

- New 380 v and 50 Hz electrical supply and distribution equipment in 1996.

- IMAL thickness measurement equipment.

- New star turner in 1996.

- IMAES N-LCSI sander.

- New IMAES Combi-4.2 sander installed in 2000.

- New Sander dust extraction and filter equipment installed in 2000.

- Large number of spare parts included.

- Civil and electrical drawings available for relocation.

- Siempelkamp 8 day light particleboard press technical specification.

- Average daily production 500 m3.

- Finished master board size of 1220 mm x 7320 mm.

- Thickness range 8 mm to 30 mm.

- Density 570 to 750 Kg/m3.

.jpg)