2700 mm deckle Twin Wire Paper Machine SOLD

General InformationGeneral Information

FOR GENERAL INFORMATION WE HAVE TO INFORM YOU OF THE FOLLOWING:

This schedule has been prepared solely for the guidance of prospective purchasers and in no way constitutes, and at no time will it be deemed to constitute, an offer or contract or any part of an offer or contract. Additionally, no warranty is given to the accuracy of any measurement, specification or other details whatsoever given within this document.

Whilst every reasonable effort has been made to verify any statement, description or comment made within the document, for avoidance of doubt it is emphasised that the purchaser must make their own enquiries and satisfy themselves.

Please note that all offers are made as lying and subject to contract.

Further technical details, photographs and videos may be available on request.

If you have any specific requirements for wood panel or paper making machinery or wish to sell your spare or redundant machinery then please contact us on john@linnmachinery.com

For more information contact john@linnmachinery.com.

X

Annual Production: 78,000 T

Deckle: 2700 mm

Operating speed max: 570 m/min

Basis weight range: 90-210 g/m²

Product: Testliner, fluting, plaster board liner.

Raw material: Waste Paper

Originally installed: 1954

Major rebuilds: 1979, 1985, 1991

Bottom layer thin stock system (1979)

Tampella TL100 pressure screen with 0.45 slotted basket

3 stage Albia cleaner system

VoithGR.31 vertical screen

Andritz pumps

Bottom layer headbox

Tampella-Carcano hydraulic headbox

Manual micro profile adjusters

2 perforated rolls

Installed 1979

Bottom layer Fourdrinier

Breast roll 607mm

Suction couch roll 1030mm

Drive roll 520mm

Foils, low & high vacuum units

Installed 1979

Top layer thin stock system

Tampella TL200A pressure screen with 0.45 slotted basket

3 stage Albia cleaner system

Andritz pumps

Top layer headbox

Tampella-Carcano hydraulic headbox

Manual micro profile adjusters

2 perforated rolls

Installed 1979

Top layer Fourdrinier

Breast roll 514mm

Wire turning roll 800mm

Drive roll 514mm

Foils, low & high vacuum units

Installed 1979

Vacuum pick up (1985)

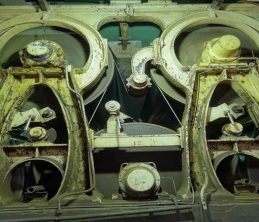

1st/2nd Press (Combi Press)

Bottom roll 540mm

Suction roll 790mm

Top roll 890mm

3rd Press (Shoe press)

NipcoFlex/Voith

Bottom felt run with 1300 mm diameter top roll

Installed 1991

Broke pulper

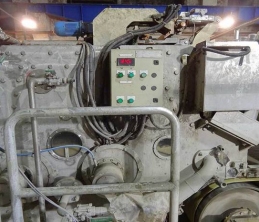

1 Nash 11 E vacuum pump & motor.

1 Nash CL3002 vacuum pump & motor.

1 Nash 10E vacuum pump & motor.

1 SulzerKRC 52-25 Turbair-Fan with associated tanks and pumps.

1 low pressure fan.

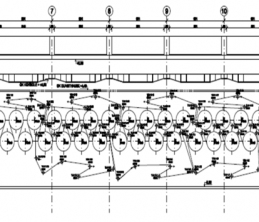

30 Pre-dryer cylinders

1 drying cylinder with 1250mm diameter

1st section (Slalom) with 7 cylinders of 1500 mm diameter

2nd section with 8 cylinders of 1500mm diameter

3rd section with 8 cylinders of 1500mm diameter

4th section with 8 cylinders of 1500mm diameter

Oil lubrication for cylinder bearings

Totally enclosed hood (1989)

Tail feeding by rope system

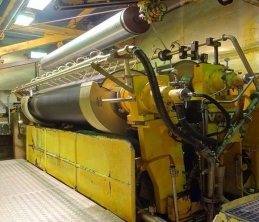

Voith-Sulzer size press

Bottom roll 800mm

Top roll 790mm

Size preparation, storage and screening

Size press UTM pulper

After Dryer 18 cylinders

2 Chrome cylinders of 1500mm diameter

5th section with 8 cylinders of 1500mm diameter

6th section with 8 cylinders of 1500mm diameter

Oil lubrication for cylinder bearings

VIB moisture profile unit

Tail feeding by rope system

Valmet IQ frame for weight & moisture measurement

Reel up UTM pulper

Jagenburg VariDur winder

Max diameter of reel 1800mm

Maximum speed 1800m/min

4 knives

AEG DC multi motor drive

Trim pulper

Lamb roll packing unit

Roll ejector, conveyor etc

Orgapack roll wrapper

Weigh scale

Labelling system

Waerag totally enclosed dryer hood with heat recovery system

Paper machine drive by AEG with 2 driven cylinders per section

Metso DCS classic system

8 machine spools

14t machine house crane with 2 hook load spreader

Water treatment plant with Krofta Sedifloat and sludge dewatering from double wire press

Spare parts, documentation and drawings as available.

Annual Production: 78,000 T

Deckle: 2700 mm

Operating speed max: 570 m/min

Basis weight range: 90-210 g/m²

Product: Testliner, fluting, plaster board liner

Raw material: Waste Paper

Originally installed: 1954

Major rebuilds: 1979, 1985, 1991