7400 mm deckle Voith Paper Machine SOLD

General InformationGeneral Information

FOR GENERAL INFORMATION WE HAVE TO INFORM YOU OF THE FOLLOWING:

This schedule has been prepared solely for the guidance of prospective purchasers and in no way constitutes, and at no time will it be deemed to constitute, an offer or contract or any part of an offer or contract. Additionally, no warranty is given to the accuracy of any measurement, specification or other details whatsoever given within this document.

Whilst every reasonable effort has been made to verify any statement, description or comment made within the document, for avoidance of doubt it is emphasised that the purchaser must make their own enquiries and satisfy themselves.

Please note that all offers are made as lying and subject to contract.

Further technical details, photographs and videos may be available on request.

If you have any specific requirements for wood panel or paper making machinery or wish to sell your spare or redundant machinery then please contact us on john@linnmachinery.com

For more information contact john@linnmachinery.com.

X

7200 mm deckle Voith Paper Machine

- Operating speed 1200 m/min

- Installed and commissioned in 1985

- Major rebuilds in 1990, 1997, 1999 & 2008

- Available for rebuild to make packaging grades

- Voith Duoformer CF wire part

- Voith tri-nip press with 4th press

- 49 drying cylinders with 1500 mm diameter

- Voith 2 roll calendar stack

- Metso QCS and DCS

- Reel up with numerous reel spools

- Siemens sectional drive

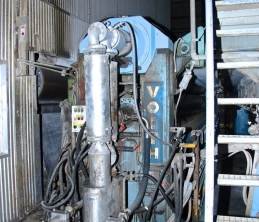

Voith Tri-nip press & 4th press

- 1st press 70 kN/m

- 2nd press 90 kN/m

- 3rd press 100 kN/m

- 4th press 120 kN/m

Drying Sections

- 1-3 Unirun design

- 4-5 Standard design

49 Drying cylinders

1500 mm diameter cylinders

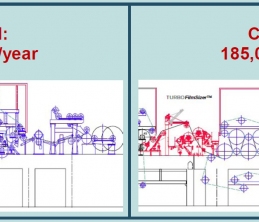

Options for rebuild include

- Additional top wire

- Film press installation

- Capacity increase to over 150,000 tonnes per year of packaging grades

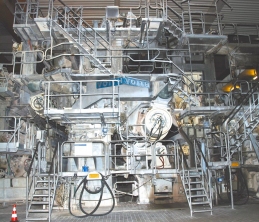

7400 mm deckle Voith Paper Machine

- Operating speed 1200 m/min

- Installed and commissioned in 1985

- Major rebuilds in 1990, 1997, 1999 & 2008

- Available for rebuild to make packaging grades

- Voith Duoformer CF wire part

- Voith tri-nip press with 4th press

- 49 drying cylinders with 1500 mm diameter

- Voith 2 roll calendar stack

- Metso QCS and DCS

- Reel up with numerous reel spools

- Siemens sectional drive